Blast it: ISO 8501-1

Procedures around blast cleaning, which is one of the most effective methods for the removal of

mill-scale and rust on steel surfaces, are described in an international standard that offers a handy

pictorial reference for coatings surveyors, applicators and supervisors to follow.

If not properly maintained and regularly treated with protective measures, most steel surfaces will

invariably degrade and start to rust over time through the effects of weathering and corrosive gases

among other factors. The International Standard ISO 8501, which ranks cleanliness levels in order

of increasing work required, specifies a series of rust grades and preparation grades of steel surfaces.

Visual assessment of the cleanliness standard of the steel surfaces, can be used to help determine the

type of paint coats and systems to be applied to a substrate.

While applicable to hot rolled steel surfaces prepared for painting by methods such as blast-cleaning,

the standard is also relevant for cold rolled steel of sufficient thickness to withstand any deformation

caused by the impact of the abrasive or the effects of power tool cleaning.

Divided into four parts, the standard’s part 1 essentially refers to the surface appearance of the steel

after preparation by either blast cleaning, hand and power tool cleaning or flame cleaning and

provides descriptions with pictorial references of the different grades of cleanliness. This aids the

grading of rust and preparation grades(Table 1) of uncoated steel substrates of different grades found

on uncoated steel surfaces, or on stored steel.

Table 1 ISO 8501-1 Rust grades

| A. Steel surface covered primarily with the adhering mill scale, with little rust if any at all showing |

| B. Steel surface that has already begun to rust slightly – mostly the adhering mill scale has begun to flake or shows large cracks which enabled the corrosion |

| C. Steel surface on which the adhering mill scale has largely rusted away or it can be scraped off, but with slight pitting visible under normal vision |

| D. Steel surface on which the mill scale has almost entirely rusted away and on which general pitting is very obviously visible in normal vision |

Once preparation of an uncoated surface or the removal of previous coatings from a surface, has been

completed, ISO 8501-1 can be used to identify the different cleanliness grades/preparation grades for

the purposes of comparison. Part 1 identifies three preparation grades that relate to the type of

cleaning method possibly used: either light, thorough/very thorough blast cleaning; cleaning until

visually clean steel (blast cleaning) hand and power tool cleaning; or flame cleaning.

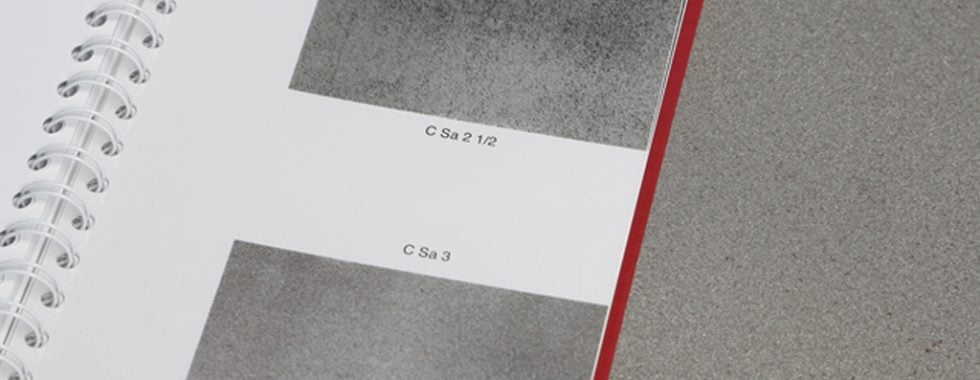

Surface preparation by blast cleaning is identified by the letters ‘Sa’ (Table 2). It is important to

remember that heavy layers of rust should be removed by chipping before blasting. The surface should

also be cleaned from loose dust and debris afterwards.

Table 2 Blast cleaning

| Sa 1 Light Blast Cleaning When viewed without magnification, the surface shall be free from visible oil, grease and dirt, and from poorly adhering mill scale, rust, paint coatings and foreign matter |

| Sa 2 Thorough blast-cleaning When viewed without magnification, the surface shall be free from visible oil, grease and dirt, and from most of the mill scale, rust, paint coatings and foreign matter. Any residual contamination shall be firmly adhering |

| Sa2½ Very thorough blast-cleaning When viewed without magnification, the surface shall be free from visible oil, grease and dirt, and from most of the mill scale, rust, paint coatings and foreign matter. Any remaining traces of contamination shall show only as slight stains in the form of spots or stripes |

| Sa 3 Blast-cleaning to visually clean steal When viewed without magnification, the surface shall be free from visible oil, grease and dirt, and from most of the mill scale, rust, paint coatings and foreign matter. It shall have a uniform metallic colour. |

Using hand and power tool cleaning to prepare surfaces is designated by the letters ‘St’ (Table 3).

Again, the same procedures should be followed as for blast cleaning to ensure a properly prepared

surface.

Table 3 St designations

| St 2 Thorough hand and power tool cleaning When viewed without magnification, the surface shall be free from visible oil, grease and dirt, and from poorly adhering mill scale, rust, paint coatings and foreign matter. |

| St 3 Very Thorough hand and power tool cleaning As for St2 but the surface shall be treated much more thoroughly to give a metallic sheen arising from the metallic substrate. |

ISO 8501-1 is one of the most used visual standards within the protective coatings industry. It is widely

specified and established. Coating Inspectors, Coating Supervisors and Contractors who supply

protective coatings to steel structures should have a good understanding of this standard.

The type and size of the abrasive used in blast cleaning has a significant effect on the profile and

produced. Hence it is important to adopt the correct methodology. More about, ISO 8501-1 and

what’s involved can be found in the Fitz’s Atlas of Coating Surveys at www.fitzsatlas.com