ASTM standards for professional coating testing

Regular and thorough evaluation of the condition of exterior paints is critical for effective long-term performance and is covered by test methods such as ASTM D660, ASTM D661 and ASTM D662.

While expert knowledge plays an important role in the completion of a coatings survey it is important to have a comprehensive appreciation of test methods such ASTM that relate to assessing weaknesses. Relying on the use of photographic reference standards, ASTM D660 is the standard test method for determining the degree of checking of exterior paints and is primarily intended to provide, through definition and illustrations, a means of evaluating film failure when checking is not always recognisable. Irregular pattern, line and short parallel, switch, crow foot, mosaic, shrinkage, short random and sigmoid are all among the many types of checking that can be identified and evaluated using this method.

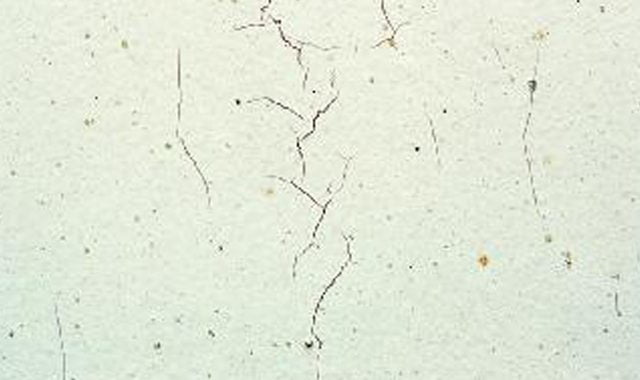

ASTM D661 should be used to evaluate the degree to which an exterior paint coating has cracked and again uses photographic standards for the purposes of comparison. A crack manifests itself in a paint film by a break extending through to the painted surface. This includes cracking in which the breaks in the film are in no definite pattern (irregular pattern type); cracking in which the breaks in the film are generally arranged in parallel lines (line type); and breaks in the film forming a pattern consisting of curves that meet and intersect (sigmoid type). If this is difficult to determine, the break can be called a crack only if the underlying surface can be seen. The use of a magnification of 10 diameters is recommended in cases where it is difficult to differentiate between cracking and checking.

Evaluation of the degree of erosion of exterior coatings is described in ASTM D662. This is a test method that identifies erosion in paint films by how much the finish has worn away to expose the substrate, or undercoat – the degree of failure is dependent on the amount of visibility and usual occurs as the result of chalking.

It’s worth noting again that when using photographic references, it is necessary to consider some precautions:

• Care must be taken not to confuse various types of failure that may be present on the same surface.

• An average portion of the film should be used for comparison. On larger surfaces it is recommended that ratings be made at several locations and the mean and range reported.

• Bear in mind that samples may vary widely in size and shape from those illustrated by reference standards – from a fraction of an inch to several inches in size.

• Factors such as moisture condition can contribute to coatings failure and when these are evident, they should be taken into consideration in any evaluation.

• Records should be kept on standard forms, such as D1150 form, or other similar ones for convenience and improved data management

Expert testing can deliver effective ratings for customers, helping to determine the viability, integrity and durability of the long-term performance of their protective coatings applications. More about what’s involved and why it’s important to adhere to ASTM and other recognised test methods can be found in Fitz’s Atlas of Coating Surveys at www.fitzsatlas.com